With the continuous development of the construction industry, the use of excavators in heavy industry machinery is increasing day by day. Firstly, it

is required that excavator manufacturing enterprises must increase production scale, and secondly, it is required to improve the production capacity

of production lines in excavator products;The production can be significantly increased, while also ensuring effective control of excavator product quality, which is an important link in the early

inspection of excavators.

The structural design of each link of the excavator is very complex, and in order to produce qualified products, it is crucial and essential to control

the quality of each link in the early stage.

But how do we detect it? What kind of testing tool can be used to solve such problems, which is both efficient and accurate?

Solution:

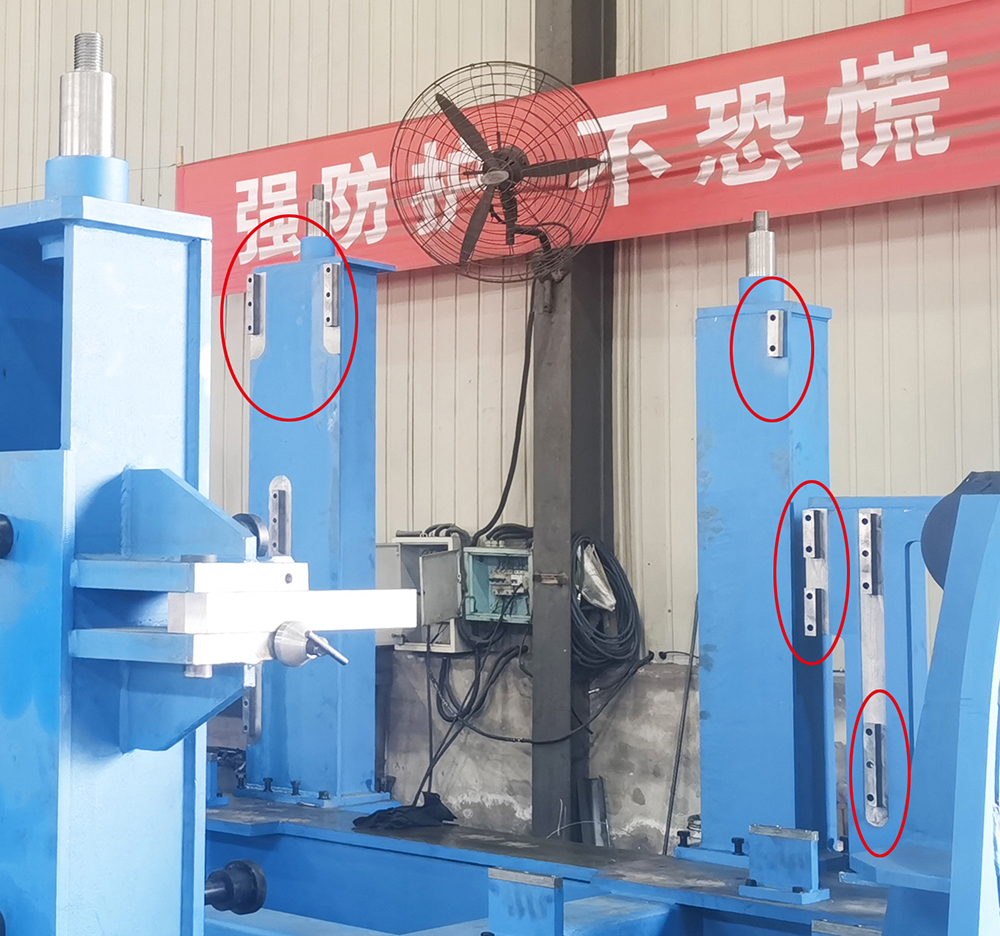

The use of portable joint arm measuring machines can effectively control product tolerances. At the same time, Huashengda is a manufacturer

specializing in measurement services with a range of up to 9 meters. For some large-sized and difficult to move products, they can be positioned

to complete the full size inspection in one go. To ensure the production of qualified products, online testing can be

achieved at any time.

In order to use excavators more flexibly during the working process, there must be deviations between the longitudinal height values and lateral

distances (or other parts) of certain components, which can cause friction and damage to the parts due to prolonged operation. In order to

reduce this error, the articulated arm measuring machine plays an important detection role, which can quickly collect and accurately measure,

and determine whether the product is within normal tolerances through this inspection method, Thus improving the detection efficiency of the

product.

By using a joint arm measuring machine, specific positional deviations of components can be obtained and corrected at any time, greatly shortening

the detection cycle and improving overall productivity.

Advantages of the plan:

1. Efficient: Measuring excavator components in minutes per hour greatly improves detection efficiency and productivity;

2. Speed: Quickly collect data, generate point cloud patterns, and combine them with mathematical models to analyze tolerances;

3. Portable and precise: Convenient to carry and move, capable of precise measurement in extremely harsh environments, suitable for various detection

scenarios;

4. Large scale inspection: For some large workpieces, it can be easily completed while ensuring its accuracy;

5. Ultra long standby: Use wireless Bluetooth connection, low energy consumption, and hard test for up to 8 hours;