The car body is composed of many components that are welded together, and welding fixture inspection is an important step to ensure that the dimensions of the car body and other components can be accurately combined together. Our ultimate goal is to produce qualified car shells.

The errors in the manufacturing and installation process of welding fixtures are inevitable, and the accumulation of errors may cause difficulties in later product assembly or batch deviations. Only by formulating solutions and adjusting the error accumulation to a controllable range, can the accuracy of product positioning be ensured. It is very important to choose a flexible and convenient measurement system. Usually, an intelligent detection device, a portable articulated arm measuring machine, is used to detect it, To ensure the accuracy of the product.

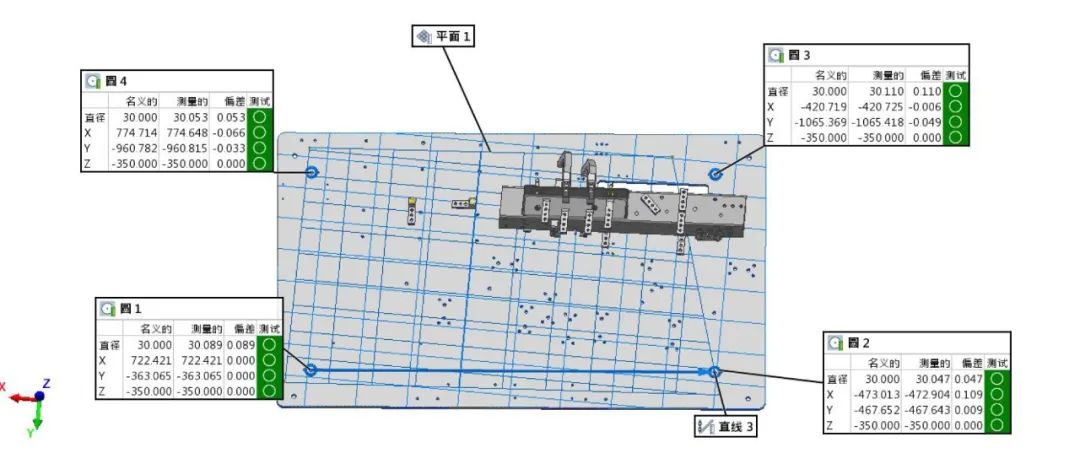

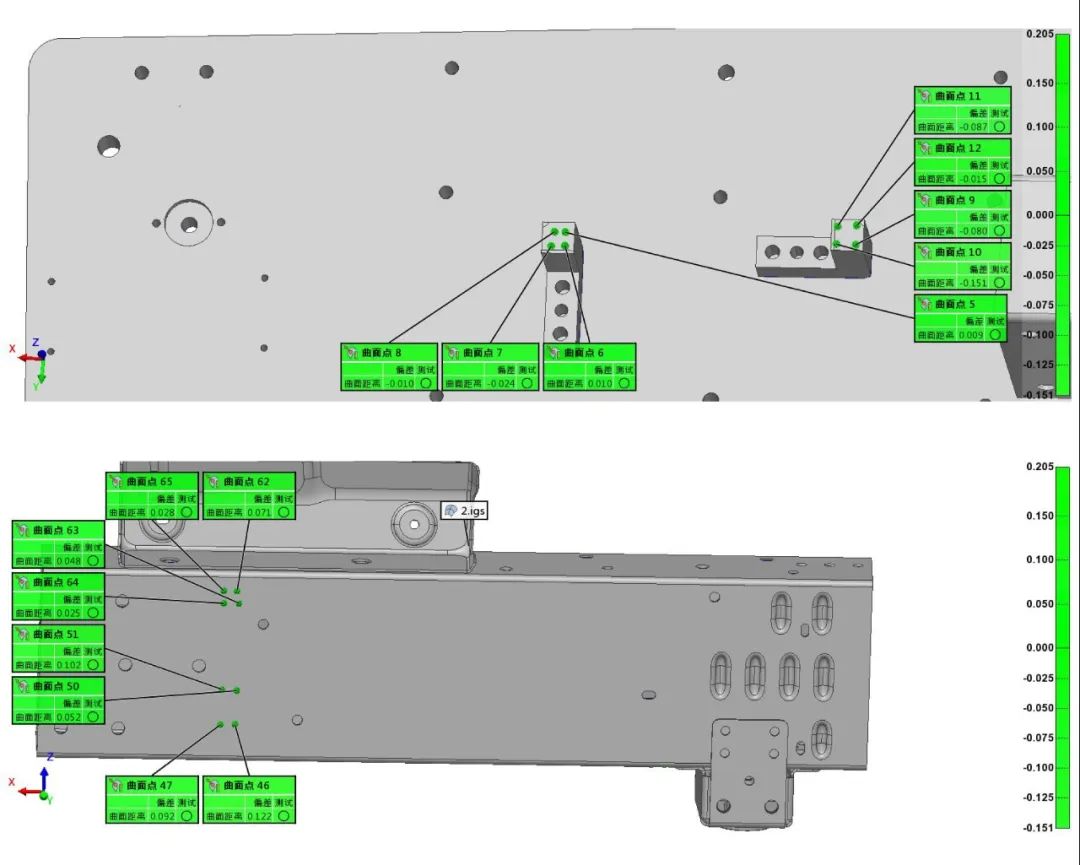

The following are the photos taken by Huashengda technical engineers during on-site workpiece inspection, assisting customers in solving a series of inspection problems in welding fixtures and component testing;

Measurement accuracy using CNA7 axis articulated arm measuring machine

Measurement accuracy using CNA7 axis articulated arm measuring machine

Measurement accuracy using CNA7 axis articulated arm measuring machine

The above data tests are all qualified.

By detecting online fixtures, reliable data analysis is provided for production quality issues such as vehicle consistency and assembly difficulties. The actual

and theoretical deviation values and adjustment plans of the fixtures are provided to ensure that the positioning dimensions of the fixtures are consistent

with the mathematical model;

When assembling the qualified fixture with the vehicle body, there is no significant deviation and it does not affect the normal progress of the next process,

indicating that the product has been verified to be qualified.

The CNA series articulated arm measuring machine has good flexibility and is not limited by any environmental temperature (built-in temperature

compensation). It can detect and scan any installation hole position and surface on the vehicle body;

Since Huashengda's technical engineers conducted real-time monitoring of production components, major enterprises and automotive OEMs have made

qualitative improvements in measurement efficiency; Greatly improve work efficiency.