In the mechanical manufacturing industry, it is necessary to upload There are many automotive components for line shape and positional tolerance

testing, such as some assembly columns. The relative spatial dimensions and positional accuracy must be ensured to meet the assembly requirements;

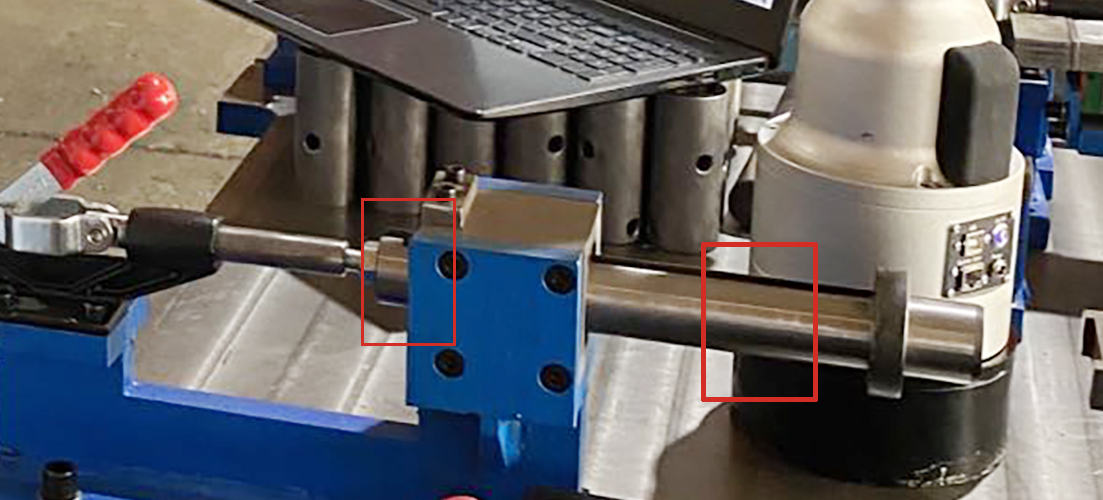

To detect the positional accuracy of these cylinders, a portable articulated arm measuring machine can be used for measurement.

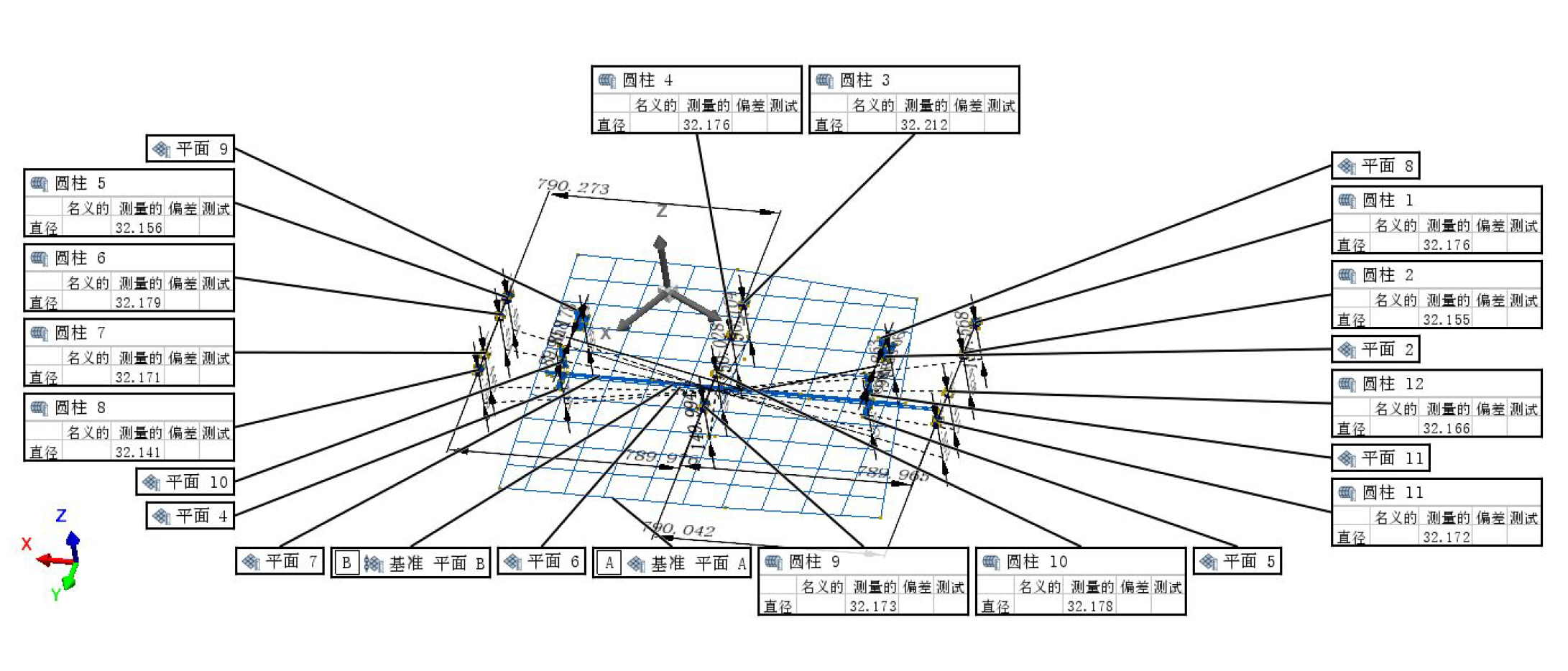

The position measurement method of portable joint arm measuring machine for measuring parts is to establish corresponding measurement features

in the measurement software according to the processing requirements of the parts, so as to accurately measure the relevant size or shape position

requirements,

This can determine whether the height of each cylinder to the reference plane is within the normal tolerance range, constrain the corresponding

dimensions, and ensure subsequent assembly, providing good guidance for later production.

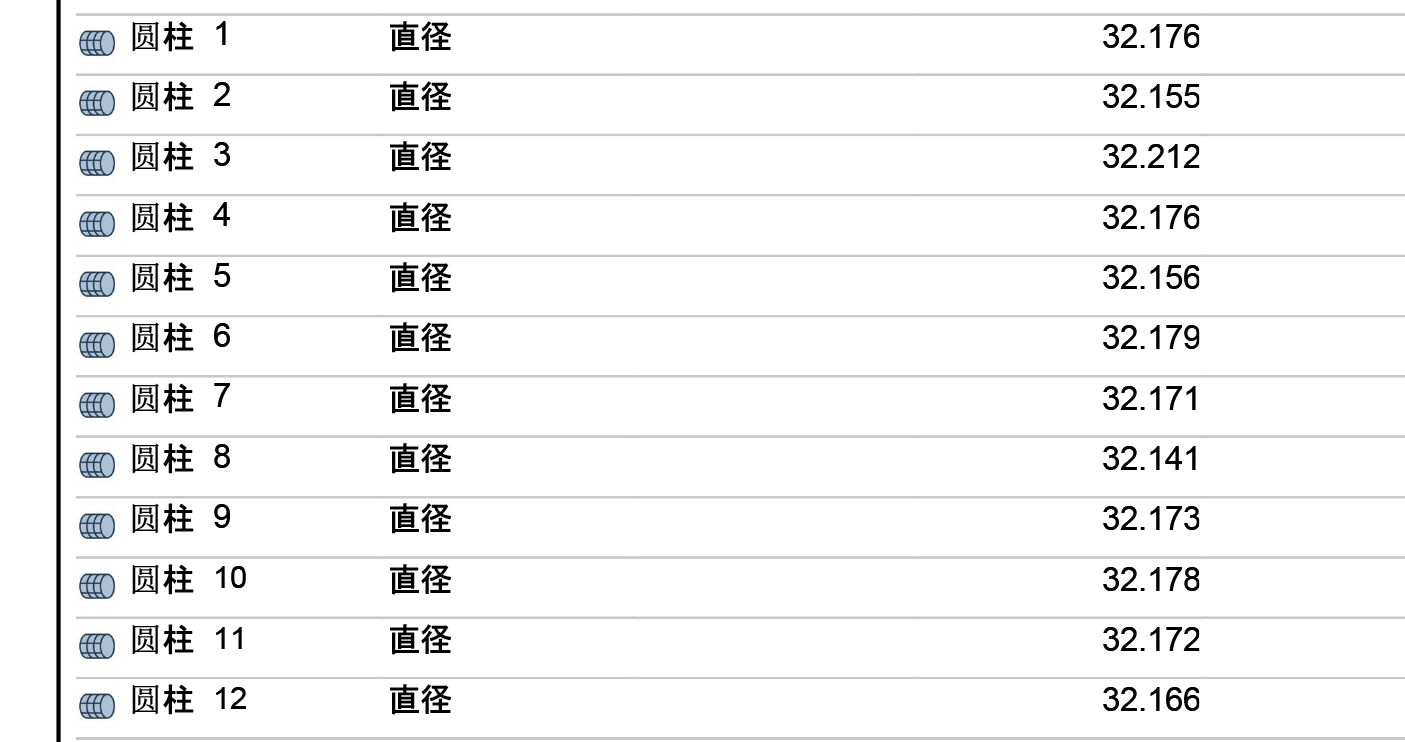

The following is the diameter measurement of a cylinder:

The data report displays:

The following are on-site photos taken for measuring the height of a cylinder to the reference plane:

The relevant size calculation results of this product are shown in the following report:

Based on the drawings of the measured parts, combined with the use of a portable articulated arm measuring machine, the workpiece can be

quickly tested for conformity. If the tolerance is large, adjustments can be made quickly, which is fast,

accuratEfficient measurement solutions greatly improve work efficiency.

The characteristic of the joint arm measuring machine is portability, which can achieve online detection function. The 9-meter long arm can solve

the problem of large workpieces that cannot be detected; Equal arm length design concept, measurement without dead angles; Unique

electromagnetic braking system,

The main arm space is locked at any position, and the arm automatically adsorbs after returning to its original position, ensuring that accidental

pulling of the joint arm will not damage the equipment; Built-in automatic temperature compensator, automatically compensating and correcting

the thermal expansion and cooling of the measuring arm caused by temperature changes

Shrinkage change, truly ensuring measurement accuracy within the range of 0-45 ℃; It can be directly used on site in the workshop, which can well

meet various measurement needs of users. Flexible and convenient installation, and allows users to save a lot of moneyTime, improving work efficiency,

and no longer wasting time for repeated measurements are all characteristics that conventional measuring tools

cannot achieve.

The portable articulated arm measuring machine can not only use traditional hard measurement, but also be compatible with different measuring

heads such as floating measuring heads, trigger measuring heads, laser forks, etc. The measuring head can be replaced at will without the need for

recalibration; In addition, in the CNA series 7-axis shutdown

On the basis of the articulated arm measuring machine, a laser scanning head can also be configured for reverse engineering, which is also a good choice.