With the rapid development of the new energy industry, the production quality of new energy vehicle batteries has been continuously improved,

and the requirements for product performance, safety, and reliability of battery packs have become stricter; At this point, an automated testing

equipment is needed to meet its accuracy requirements. Therefore, quality control, as an important link in the production and manufacturing

process, is an important condition to ensure that major manufacturers complete high-quality delivery.

o how do we ensure the assembly accuracy of new energy vehicle batteries and how do we conduct inspections?

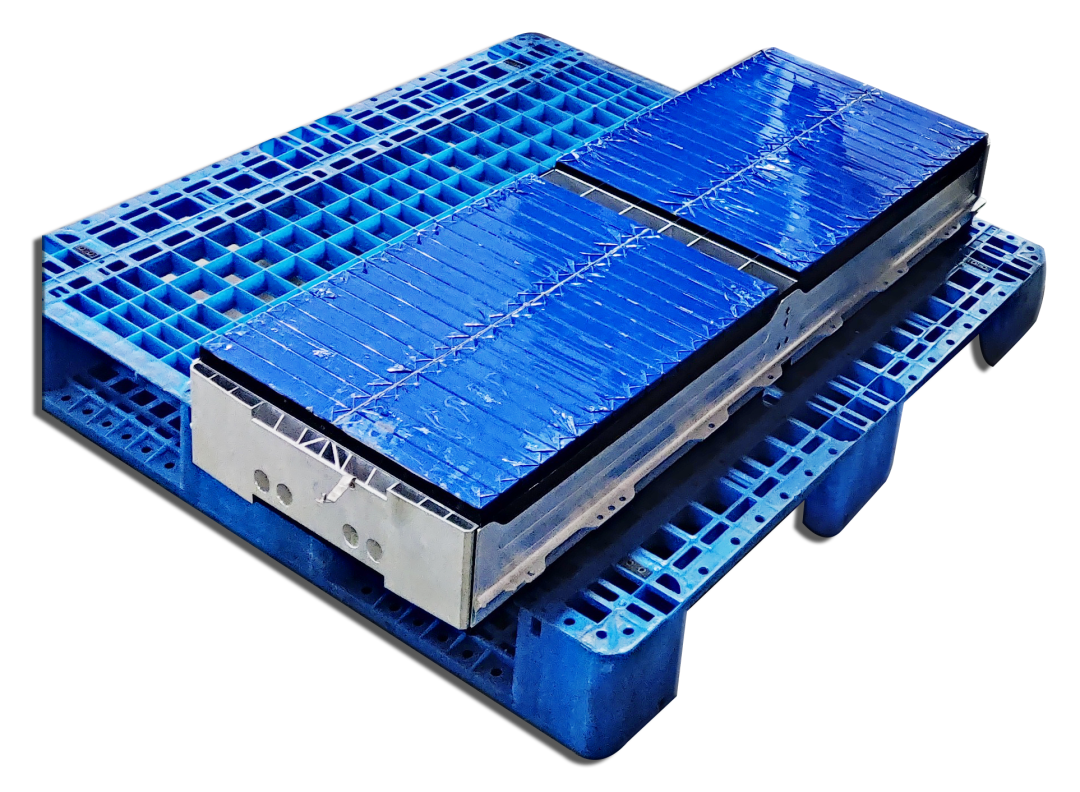

During the series connection process of the battery pack, if there are issues with poor assembly such as warping, bulging, and inability to install

the battery cover, it will directly affect the safety performance of the entire vehicle;

So, every battery shell requires strict size control. In addition to controlling the size well, it is also necessary to ensure a flatness between the

battery and the surface of the shell, which is convenient for later assembly. This requires maintaining small errors in product quality testing and

data analysis.

Detection method

New energy battery shell detection method: using a joint arm coordinate measuring machine for detection;

For the detection of large-scale battery shells, using a measuring arm is more convenient and can save a lot of manpower and equipment costs.

Data collection and accuracy verification of workpieces can be carried out, and combined with the tolerance requirements of production inspection

tools, data can be quickly adjusted.

Characteristics of articulated arm measuring machine

The joint arm measuring machine is not affected by the environment and temperature, and can move freely. Its biggest advantage is that it can

be placed and tested as needed.

1) On site measurement: The articulated arm measuring machine has no special requirements for the environment and can be used in the production

workshop. Accompanying the production line can timely detect product quality issues and reduce scrap rates.

2) Measurement of complex workpiece parts: Various fixtures, gauges, and other small and large products can be measured on-site.

3) Online detection: Traditional detection methods cannot be used for online detection, and joint arm measuring machines can be used for real-time

detection of workpieces during product processing.

By conducting on-site measurements on products, problems such as deformation and wear can be detected in a timely manner, and molds and production

processes can be adjusted in a timely manner to reduce the occurrence of subsequent assembly problems.

Integrating the joint arm measuring machine into the battery testing workflow of new energy vehicles ensures that each battery is accurately processed in

its assembly position, enabling seamless installation of battery modules; It can greatly improve production efficiency and reduce labor and production costs.

So, regardless of the industry, as long as you want to know its size and tolerance, you can use a portable articulated arm to complete testing. Moreover,

Huashengda is a manufacturer specializing in testing services. Nowadays, articulated arms have become increasingly popular and convenient to operate,

and have become one of the preferred tools in the measurement industry.